HOME < SERVICES < PFA COATING

PFA COATING

APPLICATION

- In addition to the non-stick effect, PFA coatings as a thick-film version also provide excellent chemical protection for high-temperature applications up to 250 °C.

- Adelhelm can apply PFA coatings in different versions, even for the highest demands on diffusion resistance, for layer

thicknesses of up to 2,000 Om.

- semiconductor and pharmaceutical industries due to excellent chemical resistance and low extractables (high purity)

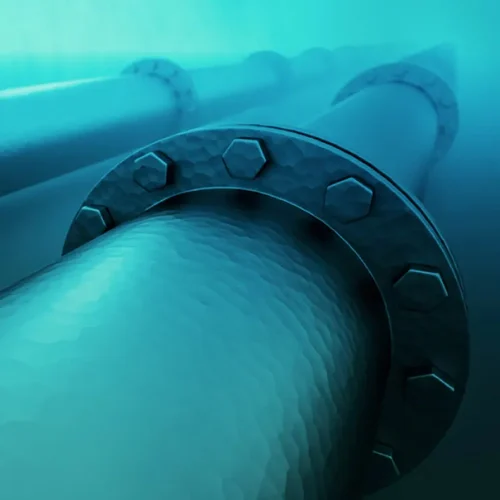

- Chemical process industries for coating of cables, tubes, pipes, fittings, pumps and valves.

BENEFITS

1. Chemical resistance.

- PFA melts and flows during curing, providing a non-porous film. This makes PFA incredibly impervious to chemicals, providing an idea coating for pumps, tanks, and vessels used in the chemical industry.

2. Superior release properties.

- PFA is a superior choice as a mold release agent because very few substances will adhere to PFA is very slippery, with a coefficient of friction of 0.10 against polished steel.

3. Outstanding temperature resistance.

- PFA is resistant to 500 F continuous. Additionally, PFA possesses good cryogenic stability, and can withstand temperatures as low as -31 0 F with no significant loss of physical properties.

4. High abrasion resistance.

- PFA is a thermoplastic and builds up significantly thicker than other fluoropolymers.This offers greater toughness than PTFE or FEP coatings. PFA is also available in an Ultra-Durable formulation.

5. FDA approvability.

- Most PFA coatings conform to FDA Regulation 175.3, and are frequently used on medical instruments and in food processing applications. PFA is ideal for pharmaceutical equipment, laboratory equipment, food processing machinery, and cookware and bakeware. Click here for more information about our medical coating products and procedures.