HOME < SERVICES < ETFE-COATING

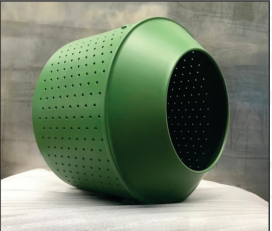

ETFE-COATING

ETFE has inherently superior adhesion when compared to most other fluoropolymers, and has been used without a

primer in a variety of applications. However, the ETFE primer approximately doubles the adhesive strength of the bond.

ELECTRICAL PROPERTIES

- Low Dielectric Constant

- High Dielectric Strength

- Low Dissipation Factors over a wide range of frequencies

- High Volume and Surface Resistivities

THERMAL PROPERTIES

- Maximum Service Temperature 302 °F (150 °C),

- Coefficient oflinear Thermal Expansion

- Deflection Temperature

FEATURES AND BENEFITS

- High film-build capabilities

- Industry-leading chemical resistance

- Very good dielectric strength

- Interchangeable and compatible liquid and powder topcoats

- A wide range of FDA-compliant options for food application

- Improved efficiency when the powder primer is used in conjunction with a complete powder system

- Compatibility with aluminum, stainless steel, and carbon steel substrates

- In-use operating temperature of 149 °C (300 °F)

- Higher Melting Point

- Higher Thermal Stability

- Lower Low Temperature Embrittlement

ETFE polymers are used commercially as the base resins for thick film coatings used in the Chemical Processing Industry. ETFE has better chemical resistance and higher temperature resistance, as determined empirically and supported by a sound basis in chemical principles. These primary advantages not only provide an extra margin of performance in chemical service, but also contribute to a more reliable application process and improved quality of the final coating.